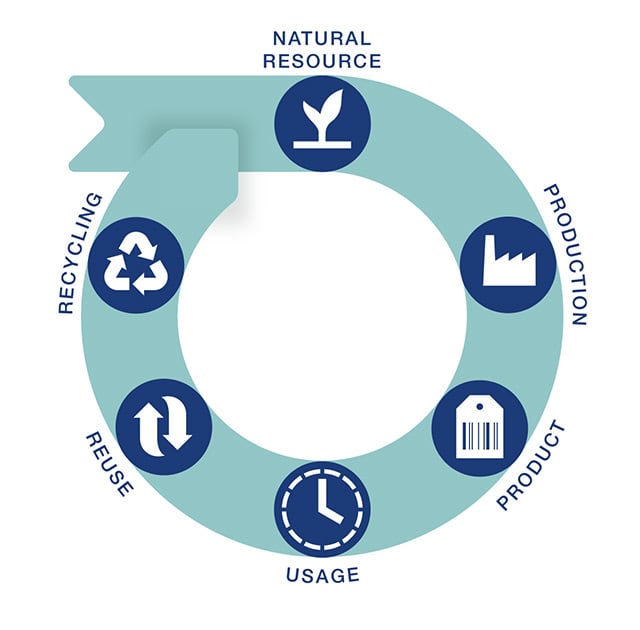

Product lifecycle

Today we live in a linear take-make-waste society. In fact, 50% of the carbon dioxide we use is embedded in products, infrastructure, and food. So, to reach net zero we need to make our material flows circular.

Alfa Laval is committed to taking care of the equipment we manufacture throughout the product's lifecycle. We design for circularity, making sure that we are careful about our raw materials. How our equipment is used is equally important, so we optimize our products over their lifetime until they can be reused and recycled.

We also believe that partnership is essential to reach net zero. By collaborating across all sectors, we can speed up the implementation of new innovations and accelerate the transition towards a more circular society.

Accelerating circularity by maximizing product lifecycle

Want to find out why circularity is such an important step on the road to net zero? Watch this short film to find out how Alfa Laval can support circularity through the product lifecycle of our equipment and why it is so important that we work together across all sectors on the road to net zero.

Product lifecycle at Alfa Laval

There are six key steps in a product’s lifecycle, and each step has its own solutions. Starting with our natural resources and production, we want to make sure that our products are responsibly sourced and produced using minimal carbon emissions. Once our products have left the production site, we want our products to support the resource savings of our customers by optimizing performance. As they reach the end of life, we offer solutions for our equipment to be reused and recycled.

Service to optimize energy efficiency

Did you know that up to 2.5% of the world’s CO2 emissions could be prevented if heat exchangers performed optimally and were serviced regularly?

Every year, the number of heat exchangers Alfa Laval services to optimize energy efficiency, reduces our customers’ capacities by 50 GW. That is the amount of energy that can be generated by 10,000 wind turbines in the same timeframe.

Imagine what we could do if all industries cleaned their plate heat exchangers to optimize heat transfer efficiency.

Re-Made to matter

There is no quick fix to our planet’s climate challenges. Every piece of the puzzle matters. That’s why Alfa Laval and Stena Recycling have teamed up to accelerate the transition towards a carbon neutral and circular future. Re-Made to matter is a programme to recycle older heat exchangers, we can minimize our reliance on virgin materials in production. At the same time, we can drastically reduce energy needs and CO2 emissions by helping customers switch to more efficient technologies. Watch this video to learn about our collaboration and solution.

Concept Zero

Concept Zero is our vision and target to produce the world’s first carbon neutral heat exchanger by 2030. It will be a heat exchanger using fossil-free steel and recycled material in the gaskets. Additionally, the heat exchanger is prepared to easily be recycled. We are doing this journey in partnership with the Swedish steel manufacturer SSAB.

Digital solutions for decarbonization

Alfa Laval and Microsoft have joined forces to reach our common goal – to reduce carbon dioxide emissions. This partnership is about utilizing the respective strengths of the two companies to create new sustainable solutions; Alfa Laval’s heat transfer solutions and Microsoft’s strength of data analysis and AI, to ensure that all heat exchangers in the world perform optimally, and to build the most sustainable data centers. A win-win-win for everyone.

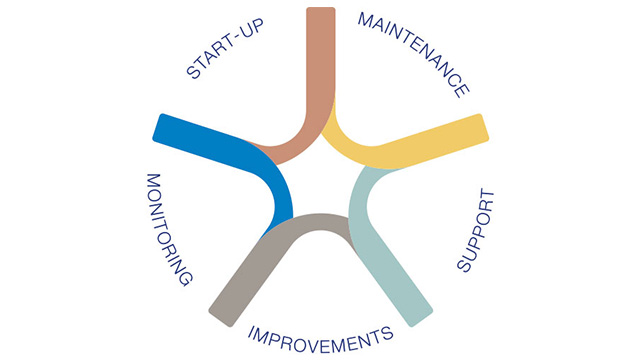

End-to-end service for endless peace of mind

No downtime. No filter changes. That’s what your customers get from the new Moatti ReMan Service Solution. We guarantee an Alfa Laval-certified, fully warranted remanufactured filter that meets like-new specifications for your customer’s regularly scheduled engine maintenance. It’s as reliable and trouble-free as an Alfa Laval Moatti automatic, backflushing filter itself.

Alfa Laval Service

Did you know that up to 2.5% of the world’s CO2 emissions could be prevented if heat exchangers performed optimally and were serviced regularly?

With Alfa Laval service, we can make sure that you optimize energy efficiency, reduce carbon emissions, and save costs over your products’ entire lifecycle.

Contact us today to find out about our 360° Service Portfolio.

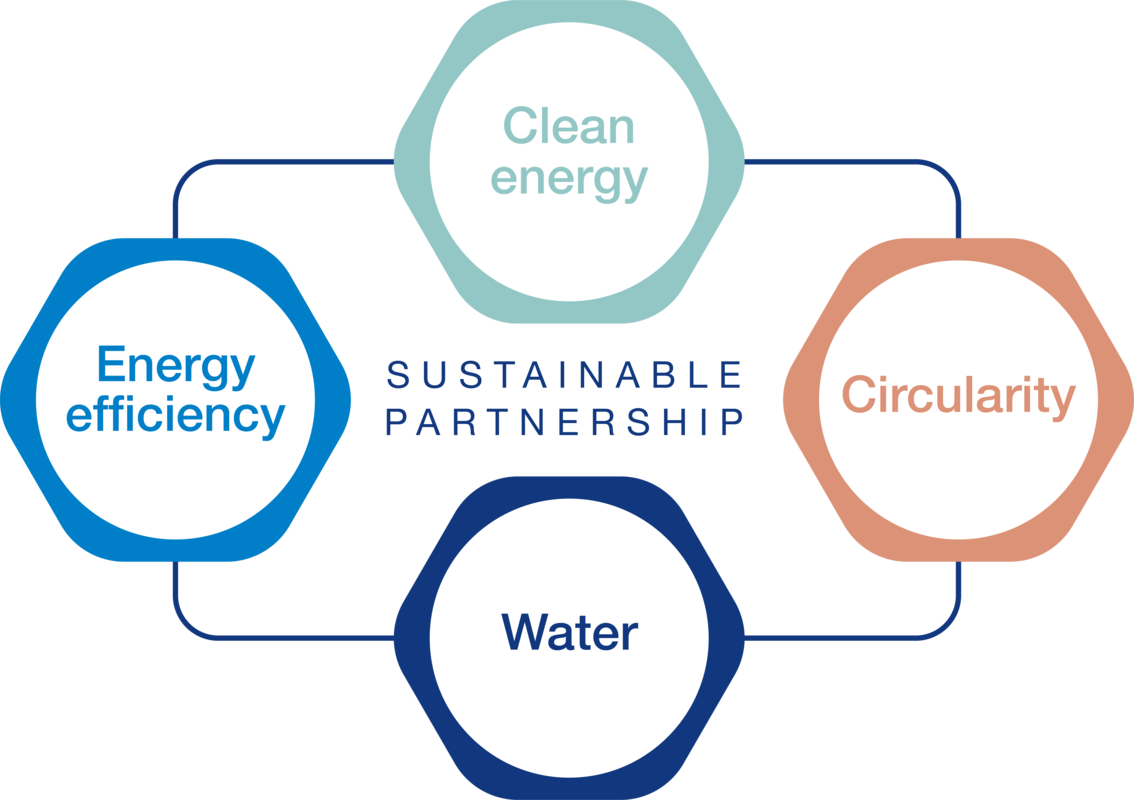

Energieffektivitet

Ren energi

Bærekraftig partnerskap

Kontakt oss for å finne ut mer

Kontakt oss i dag for mer informasjon om de bærekraftige løsningene våre