Pyrolysis

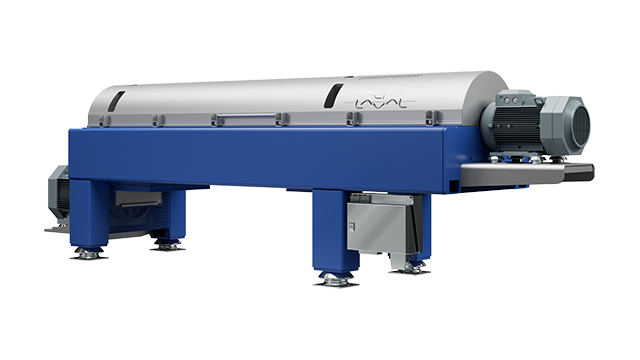

Pyrolysis is a sustainable thermal process that converts biomass and waste into value-added products such as low carbon biofuel, plastics and tyres. In the core process, materials are exposed to 600 °C temperatures in an oxygen-free environment, which causes thermal decomposition, and new molecules to form. Alfa Laval disc stack separators and decanters clean and separate valuable products in the process.

From waste to value

- Sustainable thermal process that converts wood and sawmill, worn tyre and mixed plastic waste into value-added materials

- Waste disposal is significantly reduced

- Carbon black is recovered and can be used to make new tyres

- Pyrolysis oil can also be used to make low carbon biofuel and plastics

- Sewage sludge can be converted into solid fuels or heat

The pyrolysis process

Biomass and waste are heated to temperatures exceeding 600 °C and this thermal process can transform them into and a liquid called pyrolytic oil. Alfa Laval disc stack separators and decanters then clean the pyrolysis oil in one single operation, simultaneously removing both water and particles. Output can include low carbon biofuel, plastics and tyres.

Key components

Pyrolysis output

Low carbon biofuel

Through pyrolysis, plastics, tyres and residual materials from wood production can be converted into an oil, which can then be refined into renewable low carbon biofuel.

Plastics

The pyrolysis process recovers oil from recycled plastics, which can be used as a chemical feedstock to create new plastic products.

Tires

Carbon black is recovered from recycled tires in the pyrolysis process. There are significant economic and environmental benefits since new tyres consist of 40% carbon black.