Hydraulic control oil filtration

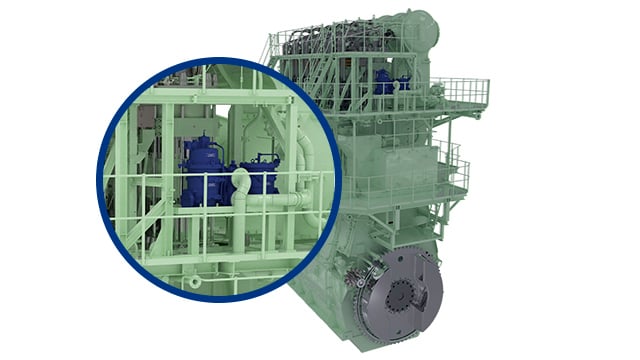

The propulsion engine landscape is evolving due to strict IMO emission regulations. In response, MAN Energy Solutions introduced the ME two-stroke engine range, which uses high-pressure hydraulic oil to actuate fuel injection and exhaust valves. Recognizing the need for advanced filtration, Alfa Laval has developed the hydraulic control oil (HCO) filter range. Fully validated by MAN ES, these self-cleaning filters protect ME engines, including dual-fuel configurations like methanol and ammonia.

Complete protection for the hydraulic control oil system

- High-efficiency filtration

- Compact design for easy installation and operation

- Fully validated by MAN ES, covering the entire range of MAN ME-C engines

- Low installation costs (CAPEX)

- Minimized energy consumption and spare part costs (OPEX)

The hydraulic control oil filter range features innovative Alfa Laval technology, enabling continuous backflushing with no pressure drop. Its compact design offers a large filtering area, with an improved distribution system for enhanced efficiency. Available in various sizes, these self-cleaning filters are designed for MAN ME two-stroke propulsion engines, providing high-efficiency filtration that protects hydraulic systems from contaminants and debris, and extends equipment life.

Products

Reduced investment and long-term savings

Why choose Alfa Laval Moatti backflushing filters for HCO filtration? Your choice impacts both upfront investment and long-term operating costs, and flexibility.

CAPEX implications

There’s more to a marine hydraulic control oil treatment system than just filtration – including hidden costs that are often overlooked in a supplier’s offer. Alfa Laval hydraulic control oil filters offer the lowest installation cost, making them a money saver for engine makers and shipyards.

They have the smallest footprint available. And don’t need electricity, marine-certified cables, compressed air or related piping. This ensures straightforward installation and significant investment savings.

OPEX implications

After the initial investment, ongoing costs can begin to add up. The choice of your hydraulic control oil treatment solution will have a major impact on your long-term expenses. Alfa Laval’s fully automatic backflushing filter range eliminates manual cartridge checks and reduces spare part consumption.

With durable, long-lasting discs and no need for electricity or compressed air, you’ll benefit from lower maintenance and fuel costs year after year.

Listen to the expert

In this insightful video, Joseph Olsson, one of our experts, discusses the critical considerations and challenges involved in selecting the right hydraulic control oil treatment system. Get valuable insights into the impact of your choice on engine performance and efficiency.

Designed for high-efficiency filtration

The hydraulic control oil filter range delivers ultra-fine particle filtration with virtually no pressure drop. Its Atrium technology offers the best footprint-to-filtering surface ratio available on the market. Each filter includes a redundancy filter, activated by a change-over valve, ensuring continuous operation during maintenance or routine oil polishing.