Marine gasketed plate heat exchangers

Alfa Laval has been developing heat transfer technology for more than 80 years and has been active in the marine industry for over a century. Based on that vast wealth of experience, our engineers have designed gasketed plate heat exchangers that set entirely new standards – not only for reliability, but also for thermal performance and ease of service.

The marine industry’s most modern line of plate heat exchangers

- Superior reliability and energy efficiency

- Small size and footprint (CompactFrame™ design)

- Minimal fouling (CurveFlow™ plate distribution area)

- Easy installation and service (five-point alignment system)

- Optimized global supply chain and production for smallest environmental footprint

Suitable for any vessel, Alfa Laval gasketed plate heat exchangers excel in applications from general heating and cooling to heat recovery, condensation and evaporation. With their innovative features, they take reliability to an all-new level and save crews time and effort during maintenance. Above all, their design minimizes fouling and maximizes heat transfer capabilities, which ensures the highest possible energy efficiency.

Nøkkelprodukter

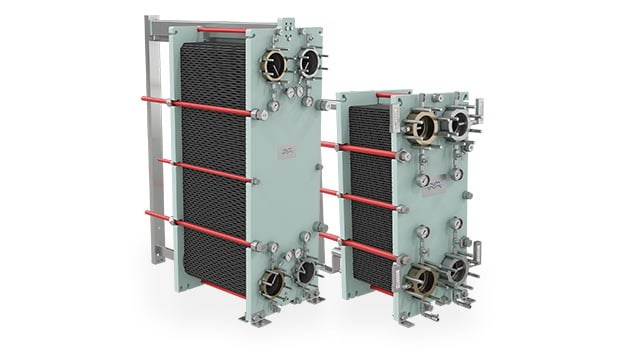

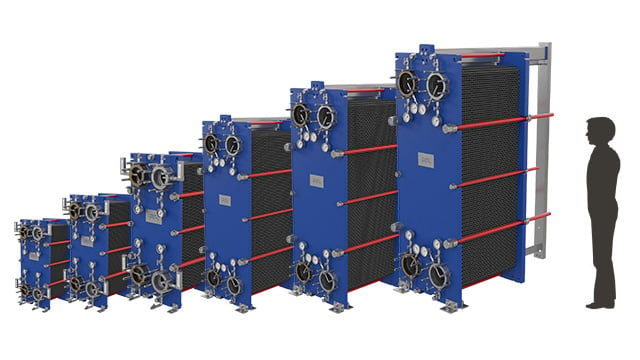

Gasketed plate heat exchangers for your vessel

Compact, reliable and energy-efficient, Alfa Laval gasketed plate heat exchangers are also safe and simple for crews to maintain. Our flexible marine line provides the right match for your needs today – with the possibility to adjust capacities later.

| T6 DN 60 |

T10 DN 100 |

T15 DN 150 |

T21 DN 200 |

T25 DN 250 |

T35 DN 350 |

|

|---|---|---|---|---|---|---|

| H (mm) | 890 | 1054 | 1833/1781 | 2082 | 2761 | 2875 |

| W (mm) | 320 | 470 | 610/650 | 755 | 913 | 1174 |

| Max flow rate (m3/h) | 60 | 160 | 370 | 650 | 1000 | 1970 |

| Capacity (kW) – water duty with LMTD 6 | 800 | 3 000 | 9 000 | 18 000 | 28 000 | 35 000 |

Slik fungerer det

Varmeoverføringsområdet til en platevarmeveksler med pakning består av en serie korrugerte plater, montert mellom en ramme og trykkplater for å opprettholde trykket. Pakninger fungerer som forseglinger mellom platene. Væskene kjører normalt motstrøms gjennom varmeveksleren. Dette gir den mest effektive termiske ytelsen og muliggjør en svært tett temperatur-tilnærming, dvs. at temperaturforskjellen er liten mellom det utgående prosessmediet og det inngående servicemediet.

Alfa Laval plate- og rammevarmeveksler med pakning for væske/væske

Features that make the difference

The Industrial line is equipped with features that turn this high-performance family into efficient and reliable workhorses that are easy to service and maintain over the whole product lifecycle.

For efficiency

By improving the efficiency of your heat exchanger, you can maximize production and minimize energy consumption to reduce your power bill and improve your environmental footprint.

See product animations below or get more information and listen to our technical experts.

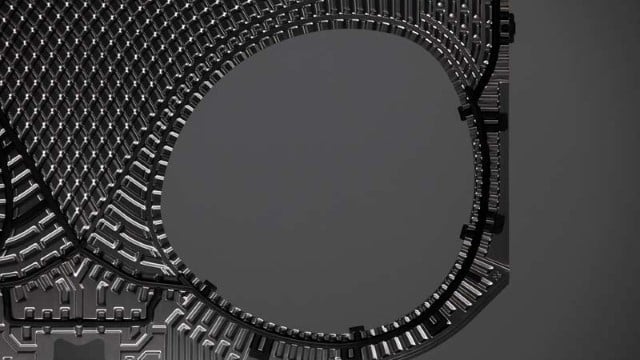

CurveFlow™

CurveFlow™

distribusjonsområde

Forbedrer medieflyten og minimerer risikoen for avleiring.

OmegaPort™

OmegaPort™

ikke-sirkulære utløpsåpninger

Forbedrer medieflyten og termisk effektivitet.

FlexFlow™

FlexFlow™

platedesign

Forbedrer termisk effektivitet og optimaliserer trykkfallutnyttelse.

For reliability

We are always looking to increase the reliability of every aspect of our gasketed plate heat exchangers.

We focus on durable designs based on robust materials and safe manufacturing processes.

See product animations below or get more information and listen to our technical experts.

PowerArc™

PowerArc™

platemønsterdeler

Forbedrer platens stivhet for lengre levetid.

Fempunkts- justering

Fempunkts- justering

Sikrer pålitelig plateposisjonering og enkel betjening for store enheter.

SteerLock™

SteerLock™

platejustering

Sikrer pålitelig plateposisjonering og enkel service.

For serviceability

The simple opening and closing of the plate-and-frame design with gaskets enables hassle-free inspection and service. It also enables you to easily adapt the unit to new process conditions.

See product animations below or get more information and listen to our technical experts.

ClipGrip™

ClipGrip™

pakningsvedlegg

Sikrer perfekt forsegling og problemfritt vedlikehold.

T-bjelkeruller

T-bjelkeruller

Gir en lavere enhet som er enkel å betjene.

Lagerhus

Lagerhus

Garanterer en enhet som er lett å åpne for jevnere, mer effektivt vedlikehold.

Kompakt ramme

Kompakt ramme

Tilrettelegger vedlikehold og minimerer krav til serviceområde

Services

Alfa Lavals maritime tjenester

Over hele verden og døgnet rundt er Alfa Lavals maritime tjenester din vei til høyere oppetid, optimalisert ytelse og trygghet. Nettverket vårt er alltid på vakt, og tjenestetilbudet gir pålitelighet, effektivitet og sikrer overholdelse av regler gjennom hele levetiden til utstyret.

24/7 Service og support

Kontakt oss hvor som helst, når som helst:

+46 4636 7700

marine.service@alfalaval.com

Vårt globale nettverk av servicesentre, distribusjonssentre og feltserviceingeniører er alltid klar til å hjelpe deg.

Documents

Downloads

Instructions and manuals

Product brochures

Heating and cooling in an engine room

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Er du på jakt etter å spare energi?

Alfa Laval setter standarden for termisk effektivitet i platevarmevekslere. Ved å kombinere innovative funksjoner, forbedre energieffektiviteten og minimere nedetiden, kan vi øke hastigheten på overgangen til mer bærekraftige løsninger og nå netto null innen 2050.

Alfa Laval technology powers sustainable operations on Maersk’s pioneering methanol-fuelled container vessel

In a world where sustainability is increasingly important, A.P. Moller-Maersk has set sail with the world’s first methanol fuelled container vessel. Equipped with Alfa Laval’s solutions for methanol as fuel, this vessel shows how innovative solutions and equipment can help shipping companies adapt to the evolving energy landscape and environmental regulations.

Krev nye standarder

Vi introduserer verdens mest moderne platevarmevekslere med pakning. Oppdag hvordan vår neste generasjon-serie med platevarmevekslere med pakning vil gi deg høyere effektivitet, bedre pålitelighet og større servicevennlighet.