Fresh yeast with less water

Water will be a significant challenge for the food and beverage industry in the coming decade in terms of sustaining and growing production at current locations. For a leading global yeast producer, the requirement for five liters of water for every 50 grams of yeast produced is already a reality. The urgency to find solutions is enhanced by regulations and public restrictions on water withdrawal for industrial use, which increasingly reflect the current pressure on water resources. For the yeast producer, this has amplified the need to treat and reuse industrial wastewater.

DATE 2024-11-21The situation has arisen due to unusually extreme weather conditions and water scarcity during summer months over the past couple of years across most of Southern Europe. Water scarcity is prompting most food and beverage producers across the region to take a forensic approach to process optimization with a view to improving water use at each production step and with a high emphasis on circularity in operations.

The global yeast producer is a family-run expert in fermentation, and at just one of their yeast production facilities, thousands of tonnes of fresh yeast are produced annually through an industrial fermentation process that requires a substantial amount of freshwater – roughly 60 to 100 tonnes of water per tonne of yeast.

With an ambition to minimize the impact on local water tables and build resilience towards unscheduled production downtime, the company set an environmental goal to maximize water reuse in the yeast production process while also increasing overall energy efficiency.

Industry collaboration leads to innovation

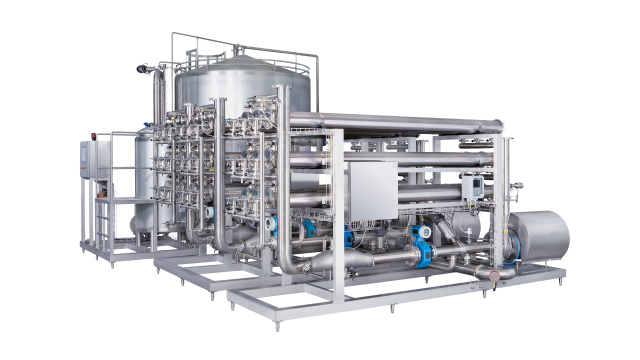

Working with industry specialists, the company consulted with Alfa Laval, a leading provider of separation technologies, and decided to introduce a membrane filtration step into the yeast production process. The membrane filtration unit sits between the centrifugal separation phase and the evaporator. The advantages are two-fold: water is removed, saving energy in the evaporation phase, and this treated water can then be reused in the processing.

“There is an even bigger potential for recovering water in the last stage of production, where vast quantities of water are lost. As part of our collaboration to continuously optimize the water footprint, we will find ways to achieve this so that it can be reused and reinjected back into the processing line,” says Alain Molina, Business Development Biotech-Pharma & Yeast at Alfa Laval.

In search of more opportunities to optimize the use of water, Alain and his speaking partners at the yeast producer are planning to visit Alfa Laval’s membrane innovation centre in Nakskov, Denmark.

Justyna Szczepanska regularly greets customers at the membrane test and innovation centre in Nakskov, Denmark.

A focus on energy efficiency

In efforts to reduce emissions and minimize costs for energy, energy efficiency was naturally in focus throughout the discussions. The use of evaporators in the process will typically be an energy-intensive process step, and the yeast producer chose the MVR evaporators. While they are still relatively energy-intensive in use, they run on electricity and consequently come with the option to convert to a renewable source of energy with a reduced carbon footprint.

“Given the energy-intensity of this process step, our efforts were also directed at reducing the actual amount of water going into the evaporator and recovering the water so that it can be reused,” explains Alain Molina.

By doing so, the membranes removed a certain amount of the water before the product passed into the evaporator. “This way, the evaporator has to remove less water and uses less electricity. The filtrated water can then be re-used in the CIP process, thereby decreasing the volume of additional fresh water required overall,” says Alain Molina.

Success paves the way for expansion

The Alfa Laval filtration system at the production facility can treat between 500 and 1,450 cubic meters of water per hour, depending on requirements.

In operation for four years now, the inclusion of a membrane filtration step is set to become a standard element at the company's production sites moving forward. “The rules are changing in relation to water quality and water reuse in industrial processing,” says Alain Molina.

He adds that in the next step of their partnership with Alfa Laval, the company wants to replicate this type of installation using Alfa Laval membrane technology and reduce the energy cost of the evaporation step at its other factories around the world.

“For now, we have engaged our membrane colleagues at the innovation centre in Denmark to evaluate the necessary specification and configuration of membranes. Each system must be adapted according to the raw materials used to grow the yeast. We give great attention to detail to each system and can adapt and adjust the characteristics of each membrane filtration system to the needs of the customer. This is a key part of the success of Alfa Laval.”

Fremhevede teknologier

Vannbesparelser

Membrane modules supplied by Alfa Laval treat between 500 and 1,450 cubic metres of water an hour. The water can then be recycled for use for cleaning purposes.