AlfaPure

The Alfa Laval AlfaPure range comprises purpose-built centrifugal separator systems for removing oil, grease and solid particles from water and oil based liquids, such as coolants, lubricants and wash liquids.

Efficient cleaning of service fluids pays off

Utilizing centrifugal separation, the Alfa Laval AlfaPure range is a series of extremely efficient systems for cleaning industrial service fluids, such as coolants, wash liquids and mineral oils. Removing oil, grease or particles from these fluids makes them last much longer and reduces machine tool wear, leading, in turn, to increased uptime in your plant. It also results in cleaner, healthier working conditions in the workplace.

Longer service life for fluids

Continuous cleaning extends the life of wash liquids by up to six times, while coolants can be made to last as long as ten years, with dramatic savings in replacement costs. The costs of disposing of contaminated liquids and filters are also greatly reduced.

Extremely efficient cleaning

Centrifugal separation is the most efficient method available of cleaning service fluids. It removes water, abrasive metal fines and other particles as small as 2 μm, therefore machine tools give much longer service before wearing out. This means considerably lower tool replacement costs. Reduced tool wear also results in more precise machining and fewer rejects.

Complete system design

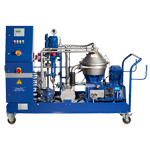

Alfa Laval AlfaPure systems are built around centrifugal separators. Each system is a complete plug-and-play module, including separator, feed pump, sludge pump and an easy-to-operate control panel, a PLC control system that handles all valve and pump settings automatically. Normally installed in a bypass system, the unit operates continuously without interrupting machinery operations. This also means no plant redesign is needed

Optimized to your needs

Several Alfa Laval AlfaPure systems are available to choose from, enabling to find the best available solution for different applications. Check our product range shown below and look at the technical details in the documentation section.

AlfaPure S2

|

Application:

Flow rate max capacity (L/h): |

|

AlfaPure S3

|

Application:

Flow rate max capacity (l/h): |

|

AlfaPure Z7-5

|

Flow rate max capacity (l/h): |

|

AlfaPure Z7-7

|

Application:

Flow rate max capacity (l/h): |

Hvordan det virker

Ten thousand times faster than settling

In a centrifugal separator, the gravity that causes separation in traditional settling tanks is replaced with a centrifugal force that can be more than 10,000 times stronger. Naturally, this makes separation much faster and more efficient.

Revolutionary disc stack technology

If buffer plates are added to a settling tank, the sinking of any particles stops sooner and there is a greater surface area on to which they will fall, helping speed up the separation process. In a centrifugal separator, the same basic principle can be applied, and a corresponding increase in effectiveness achieved, by a stack of special discs.

The ingenious separation process

In the separator bowl, during the separation process, the centrifugal force presses any heavy particles present in the service fluid outwards against the walls of the separator, and will automatically be discharged from the bowl to the sludge tank. Density differences, if two liquid phases are present (such as coolant and tramp oil, or mineral oil and water) will cause the two phases to separate. The light phase and heavy phase will exit separately through different outlets of the separator.

This makes centrifugal separators an extremely effective way to remove solid particles from many different types of service fluids, as well as separating out different liquid components – all at the same time.

By pass installation

Normally installed in a bypass system, Alfa Laval AlfaPure operates continuously without interrupting machinery operations. This also means no plant redesign is needed.