Damp- og varmegenerering

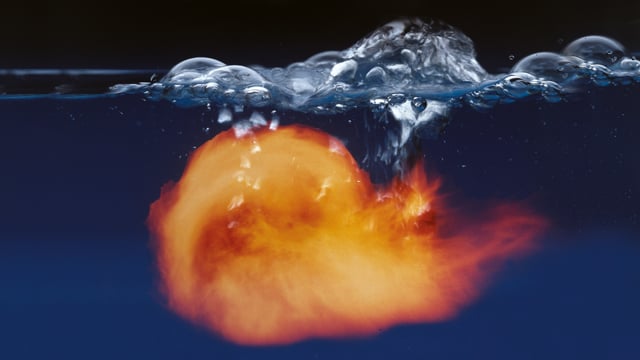

Steam and heat have a fundamental role in many onboard processes. Whether by using oil and gas or by economizing the energy already in motion on board, Alfa Laval finds increasingly efficient ways to generate steam and heat – and to distribute them where they’re needed most.

A century of skill in heat supply

Alfa Laval’s Aalborg steam and heat generation solutions represent a unique body of knowledge. They stand for nearly 100 years of innovation, from energy-efficient pin-tube boiler elements to composite boilers and low-pressure thermal fluid systems.

Even more importantly, they stand for thermal expertise. Because we understand the consumers as well as the producers of steam and heat, we can fine-tune the production for the greatest energy efficiency downstream.

Creating optimized thermal systems

Advances are still being made. For instance, the low-maintenance Aalborg boiler concept is entering a new generation. Suffixed TCi (Turbo Clean, intelligent), the self-cleaning boilers do away with water washing and the need for effluent disposal.

But the greatest advances come from linking technologies together. Our Energy Management System for thermal fluid, for example, reduces fuel use by prioritizing heat distribution according to the needs of connected consumers. And today we’re exploring not only new boiler constructions, but also new ways of combining equipment an for even greater effect.

Download

Steam production and waste heat recovery