Upgrading ginseng extract concentration system improves functional food quality

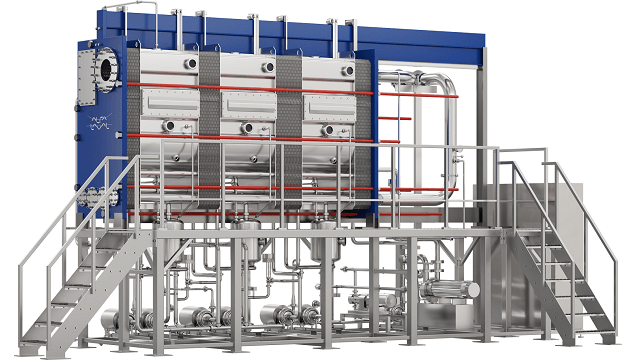

Daedong Korea Ginseng, a premier producer of functional ginseng based foods, set out to increase production capacity by 60% to meet steadily growing market demand. The company also decided to build a new production facility while, at the same time, optimizing its factory footprint. Among the company’s strategic objectives: improving thermal efficiency and simplifying operations and maintenance of its ginseng extract concentration lines. The solution? The Alfa Laval AlfaVap Inline customized for concentrating ginseng extract. Compact and pre-assembled, it boosts product quality and productivity while reducing labour costs by 50%, installation height by up to 20%, and energy costs by up to 10%.

DATE 2024-02-27

Established in 2002, Daedong Korea Ginseng produces raw ginseng, concentrated extract, ginseng extract powders, and fermented products under its brands and sells ginseng extract to food, personal care, and pharmaceutical manufacturers. Processing involves multiple drying and heat treatments. After the ginsenosides are extracted from the raw roots, the double-effect AlfaVap Inline effectively evaporates most of the process liquid to achieve highly concentrated red, white and black ginseng extracts before sterilization and packaging.

Better product quality with shorter retention times

Because ginseng is heat sensitive, heat stress can cause ginseng extract to become dark and turbid. Using the AlfaVap Inline evaporator minimizes the thermal impact on the product with no loss of organoleptic and functional properties.

With the Alfa Laval plate evaporation system, we achieve better ginseng flavour.

Mr. Lee Kumwoo, Production Manager at Daedong Korea Ginseng

“Ginsenosides, which are key ginseng components, are sensitive to heat. Unlike our previous evaporation system, the AlfaVap Inline has a shorter residence time, minimizing product heat exposure. Our ginseng concentrate now has a clearer, purer colour.”

For quality assurance, the onsite Daedong lab verifies the advantages of the double-effect AlfaVap Inline evaporator. For instance, the lab can determine the content of heat-sensitive ginsenoside Rg3, an essential component that enhances colour and taste.

Compact footprint, low capital expenditures

With the AlfaVap Inline, Daedong Korea Ginseng has greater flexibility to increase production capacity as global demand increases. Versatile and energy efficient, the AlfaVap Inline has a smaller footprint and is 20% lower in height than the shell-and-tube evaporation systems the company used, making the new system more economical to install, operate, and maintain. Preassembled and pretested before delivery, the skidded evaporator module typically requires only two days to install instead of the 30 days required by other systems.

The only work required on-site is connecting the unit to the utility lines, reducing the time and cost for installation and commissioning. All instruments and gauges are easily accessible to inspect and service from a built-in platform, simplifying maintenance requirements.

Same output in 30% less time using 10% less energy

With the AlfaVap Inline, Daedong can maintain its production capacity while reducing production time by up to 30%. The compact design and straightforward operation also minimize energy consumption, saving up to 10%. Moreover, the AlfaVap demonstrates high evaporator efficiency due to a good heat transfer coefficient and unique corrugated plate pattern, creating a turbulent flow that promotes a self-cleaning effect and minimizing cleaning frequency and downtime.

The energy savings directly translate into a 10% reduction in carbon footprint. More importantly, the compact, space-saving design of the AlfaVap Inline uses less steel, takes up less floor space, and reduces ceiling heights compared to conventional evaporators. Shrinking the facility’s overall footprint increases cost savings and reduces carbon emissions further. Moreover, it is more resource-efficient, enhancing processing efficiency and reducing waste.

Fremhevede teknologier

Scope of supply

• Alfa Laval separators

• Alfa Laval decanter

• Alfa Laval AlfaVap Inline rising film plate evaporator

Reduced footprint of equipment

20% reduction in installation height

Uptime

Up to 30% savings in production time

Cost savings

50% savings in labour costs

Energy savings

10% reduction in energy costs