AlfaNova AQ

The Alfa Laval AlfaNova AQ fusion-bonded plate heat exchangers are aimed at HVAC applications. The range is AHRI Certified® through the Liquid to Liquid Brazed & Fusion-Bonded Plate Heat Exchangers (LLBF) Certification Program to ensure thermal performance. The performance certification verifies that the product performs in accordance with the manufacturer's published rating. They are used in applications such as district energy systems, potable water heating and free cooling systems.

The Air Conditioning, Heating and Refrigeration Institute (AHRI) Standard 400 certification is an independent, third-party verification of thermal performance. Through its certification program and standards, AHRI strives to help customers save energy, improve their productivity and help to ensure a better environment.

AHRI Certified™ is the trusted mark of performance assurance for heating, ventilation, air conditioning and commercial refrigeration equipment. Products earning the mark undergo rigorous, independent annual evaluation to ensure that they perform according to the manufacturers’ published claims. Certifying HVACR equipment and component performance allows consumers to compare products based on independently verified performance ratings. To find AHRI Certified™ products, go to the AHRI directory.

AHRI Certification Procedures and Benefits

To certify a product to AHRI standards, the manufacturer submits specifications and performance data to AHRI for performance evaluation and potential certification.

Once certified, buyers and users can be assured that:

- The plate heat exchanger will perform in accordance with the manufacturer’s published ratings.

- Product performance can be easily compared for their specific application.

Alfa Laval AlfaNova AQ plate heat exchangers are made of 100% stainless steel, with the components fused together using a break-through technology that Alfa Laval has patented. This provides levels of hygiene and corrosion resistance unmatched by any other brazed heat exchanger. It also makes it practical to use stainless steel plate heat exchangers in installations normally reserved for conventional semi-welded and welded units.

Resistance to corrosion also makes Alfa Laval AlfaNova AQ popular in district heating installations in which corrosive water is used. The hygienic heat transfer channels and mechanical strength also make Alfa Laval AlfaNova units ideal in applications where the prime focus is on hygiene, such as clean water refrigeration chillers and tap water heating systems.

Cost effective for everyone involved

End-users

- Reduces lifetime operating costs significantly by assuring a more energy-efficient system

- Ensures full investment value by reducing costs for field tests and additional component performance margins

Consultants

- Allows for the design of a system in which all the major components are independently performance certified

- Ensures that targets on power consumption and climate control can be met

- Provides a verifiable basis for heat exchanger selection

- Protects the owner and consulting engineer from performance concerns during commissioning and after installation

Contractors

- Ensures that all certified plate heat exchangers included in proposals will deliver the stated thermal performance

- Reduces troubleshooting time during commissioning and after start-up

The Air-Conditioning, Heating, and Refrigeration Institute (AHRI) Product Performance Certification Programme is a voluntary programme, administered and governed by AHRI, which ensures that various types of heating, ventilation, air conditioning, refrigeration, and water heating products perform according to manufacturers’ published claims.

Products that are certified through the AHRI Product Performance Certification Programme are continuously tested, at the direction of AHRI, by an independent third-party laboratory, contracted by AHRI, to determine the product’s ability to conform to one or more product rating standards or specifications.

Hvordan det virker

Heat transfer technology involves bringing two substances at different temperatures close to each other so that one either heats or cools the other.

Design

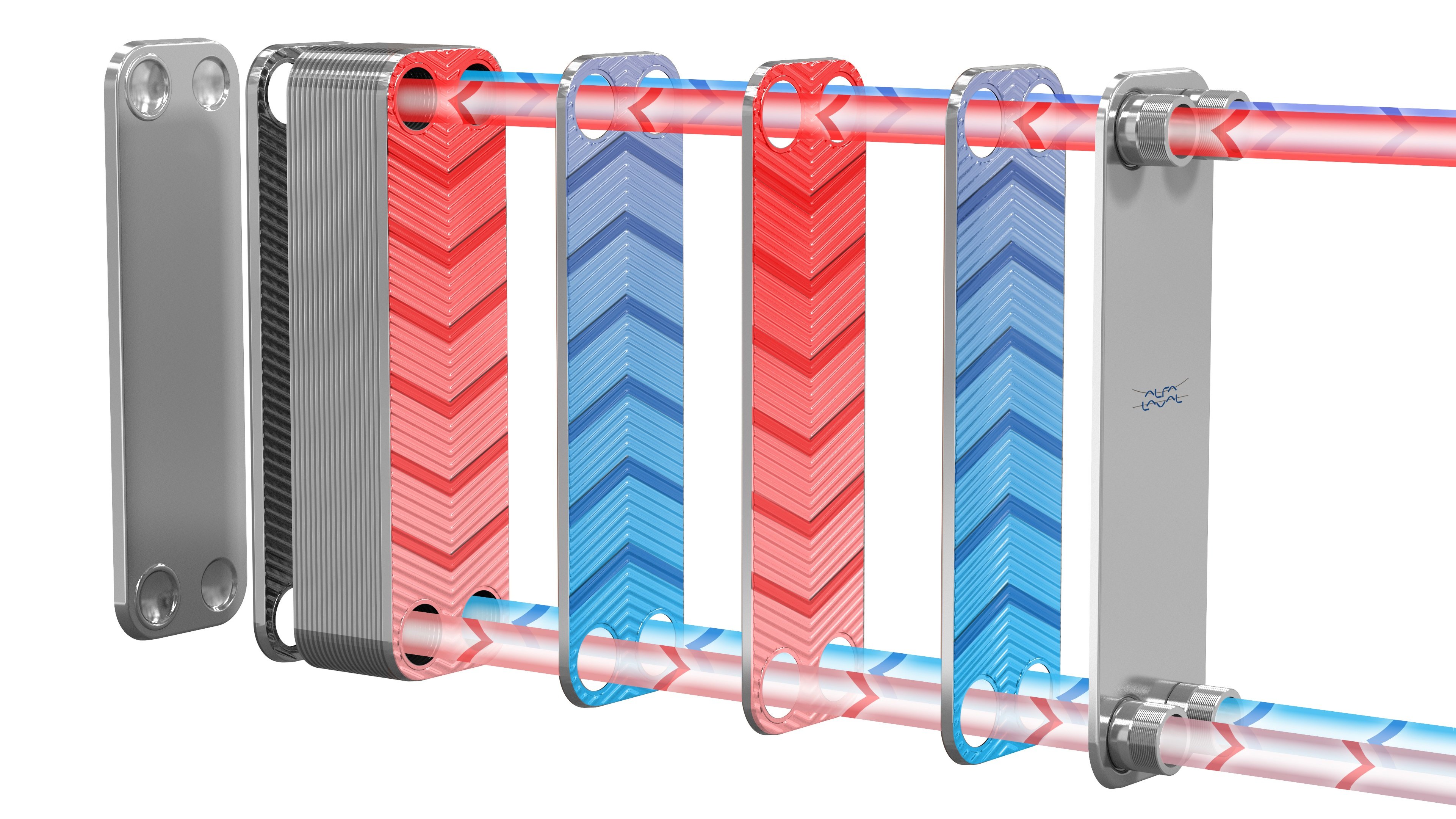

Alfa Laval AlfaNova Fusion-bonded plate heat exchanger consists of corrugated stainless steel plates, a frame plate and a pressure plate. The heat transfer plates in the plate pack are bonded together using AlfaFusion technology, a unique method of bonding stainless steel components that are an Alfa Laval patent.

The AlfaFusion bonding seals and holds the plates together at the contact points ensuring optimal heat transfer efficiency and pressure resistance. The plate design guarantees the longest possible life. Distributing the load across many separate contact points provides excellent resistance to pressure fatigue. Bonding the stainless steel plates together eliminates the need for gaskets and thick frame plates.

Working principle

Channels for the fluids are formed between the plates. The two fluids flow in alternate channels in a counter-current flow pattern in order to achieve the most efficient heat transfer. The transfer of heat energy from one fluid to the other takes place over the large surface. The corrugation of the plates is specially designed to induce maximum turbulence and even distribution of both the fluid flows in order to make heat transfer as efficient as possible.

Material

Alfa Laval Fusion-bonded plate heat exchangers consist of solid stainless steel grade AISI 316.

Cleaning

The turbulent flow in the heat exchanger has a self-cleaning effect. However, if cleaning is still necessary, learn more on about CIP (Cleaning-in-place).