EN 1.4307 / AISI304L

Stainless steel type 1.4307, also known as grade 304L, is a versatile and durable specification of stainless steel. Widely used in the food industries, 304L stainless steel is a cost-efficient alternative to the AISI316L specification and is known for its outstanding weldability, corrosion-resistance properties, and suitability for use in both hot- and cold- working environments.

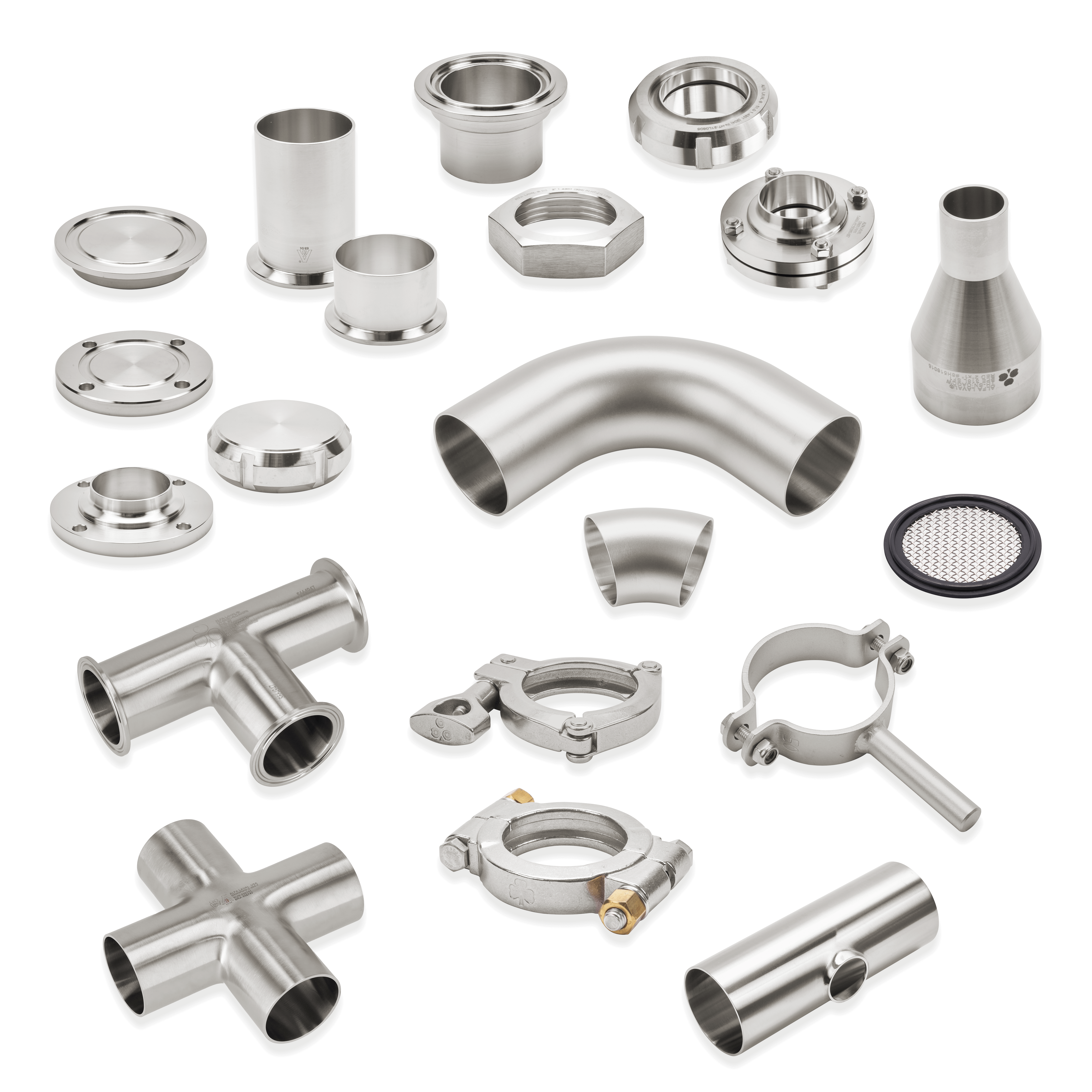

Alfa Laval pumps and valves are among the world’s leading products manufactured using 1.4307 / AISI304L, with a wide range of stainless steel tubes, bends, fittings, and connectors available. Primarily used in the food industries, all 1.4307 stainless steel used in Alfa Laval pipes benefits from the high quality assured by the Standard EN10217-7, which facilitates compliance with Pressure Equipment Directive (PED). In most cases the Alfa Laval tubes and fittings also comply to the Boiler and Pressure Vessel Code (BPVC) which is mainly used in the US but also in other parts of the world.

All Alfa Laval products are manufactured to guarantee compliance with the highest standards in each local market they are available in around the world. All Alfa Laval stainless steel pumps and valves and AISI304L tubes, pipes and connectors deliver outstanding quality, both locally and globally. Whether it is EN1.4307 / AISI304L or the also commonly used standard for the bio- and pharmaceutical industries EN 1.4404 / AISI316L.

Kontakt oss

Visste du at rør og fittings utgjør 90 % av væskens overflatekontakt gjennom hele prosessstrømmen?

Se animasjonen og lær hvordan rør og fittings er den vitale ryggraden i enhver prosesslinje.

Finn produktene du leter etter

Den digitale Alfa Laval-produktkatalogen gjør det enkelt å finne og velge produktene du trenger. Når du ber om et tilbud, vil katalogen vise Alfa Lavals partnere i din region – og du kan sende forespørselen din direkte.

EN 1.4307 / AISI304L Material Properties

1.4307 / AISI304L / S30403 is an austenitic stainless steel, composed primarily of chromium and nickel. Many standards of stainless steel exist but in Alfa Laval we mainly use AISI304, AISI304L, 316 and 316L. 304 stainless steel, commonly also known by the designation 1.4301, is ranked as the most widely used of all stainless steel specifications and is easy to form, weld and fabricate. Stainless steel type 304L is a low carbon version of AISI 304, with only a minor chemical difference between the two specifications.

The high percentage of chromium in 304 and 304L offers superior resistance to corrosion. The presence of small amounts of carbon and manganese in these grades provides improved resistance to oxidation, resulting in surfaces that can be easily sanitized and kept clean.

Grade 304L stainless steel is commonly used in heavy gauge components, offering improved weldability and can be processed into a variety of forms, including sheet, roll, tube, pipe, bend, and plates.

Benefits of AISI304L over AISI316L

When faced with the choice between the similar grades of stainless steel, are there any benefits or major advantages or differences between AISI304 and 304L over AISI316 and 316L grade products?

Perhaps the most fundamental difference between AISI304L and AISI316L grades of stainless steels is the higher amount of nickel and the presence of molybdenum present in the 316 alloys. This composition offers increased chemical resistance than that of 304 and 304L stainless steels. However, this higher-spec composition makes 316 and 316L stainless steels a more expensive option than the 304 and 304L grades.

While both 304L and 316L stainless steels offer excellent durability and long-term reliability when exposed to water, corrosion-resistance properties of AISI316 grade stainless steels are superior to those of 304 and 304L when in contact with high concentrations of salt and strong acids. If neither of these are a concern for your intended usage, then the 304 and 304L variants will be an appropriate and reliable option.

Additionally, the melting point of the 304 stainless steels is between 50 to 100 degrees higher than for 316 and 316 stainless steels, so is a factor to bear in mind when choosing between the two grades

Water Tolerance of 1.4307 / AISI304L

1.4307 / AISI304L stainless steel continues to be reliable and effective when exposed to or submerged in water and other fluids. However, in coastal environments, 316L is recommended for use, due to its superior durability when in contact with marine water. 304L is suitable for outdoor use, with high levels of resistance to atmospheric corrosion. As is standard for all stainless steel products, regular contact with acids may gradually cause wear to AISI304L tubes and other stainless steel fixtures.

Care and maintenance of AISI304L stainless steel components is straightforward, with a simple detergent process recommended for cleaning the surface.

Corrosion Resistance of 1.4307 / AISI304L

1.4307 / AISI304L has excellent corrosion-resistance properties. 1.4307 / AISI304L is a versatile, multi-purpose stainless steel, suitable for use in outdoor environments, with a high-level of durability to the elements. AISI304L is the recommended variant for use over 304 when a fluid contains mild acid or low concentrations of salt. In fluids with strong acid or a high concentration of salt we recommend you use 316L pipes and fittings. Please contact your local Alfa Laval sales office in case you have any questions about which grade to choose.

Heat Tolerance of 1.4307 / AISI304L

Stainless steels, such as 1.4307 / AISI304L, have excellent heat-tolerance properties, making them a suitable and accessible material in most typical manufacturing conditions. Commonly used at temperatures between -20 and 200°C, 1.4307 / AISI304L has a melting point of 1450°C.

For fabrication processes at temperatures between 425 and 860°C, AISI304L is recommended in preference to AISI304, due to its improved resistance to carbide precipitation. A high Carbon alternative, 304H, is recommended for continuous use at higher temperatures.

Cold-Working with EN 1.4307 / AISI304L

Durability at all temperatures is a key benefit of 1.4307 / AISI304L, which is frequently used in cold-working processes and used in subzero conditions. Cold-worked parts formed of 1.4307 /AISI304L may require a stress-relieving annealing process to reduce internal stress Please ask your local Alfa Laval partner if you need further assistance or use the RFQ formular at the top of this page.

Weldability

1.4307 / AISI304L stainless steel can be welded by most resistance welding techniques and is most commonly used in both TIG welding and orbital welding. AISI304L is recommended for use in heavier sections to lower the occurrence of carbide precipitation.

Polishing

Electrochemical polishing techniques work well on 1.4037 /AISI304L stainless steel to achieve a highly polished finish. As well as creating an appealing visual appearance, polishing stainless steel improves its resistance to corrosion. It is also easier to keep polished stainless steel clean, lowering the risk of bacteria being retained on the metal’s surface.

Additional questions

At Alfa Laval we are specialized in advising which standard is the most suitable for your purpose. With a wide range of all market standards, we can independently advise you whether you work in the dairy, food, beverage, home & personal care, biotechnology or pharmaceutical industry.

Chemical compositions (EN 1.4307/AISI 304L)

|

Chemical element |

Percentage |

|

Chromium (Cr) |

17,5 – 19,5 |

|

Nickel (Ni) |

8,0 – 10,5 |

|

Manganese (Mn) |

2,0 |

|

Silicon (Si) |

1,0 |

|

Phosphorous (P) |

0,045 |

|

Sulphur (S) |

0,015 |

|

Carbon (C) |

0,03 |

|

Iron(Fe) |

Balance |

Physical properties (EN 1.4307/AISI 304L)

|

Property |

Value |

|

Melting point |

1450 °C |

|

Density |

8.000 kg/m3 |

|

Thermal conductivity |

16,2W/m.K |

|

Thermal expansion |

17,2 x 10-6 |

|

Electrical resistivity |

0,072 x 10-6 Ω .m |

|

Modulus of elasticity |

193 GPa |

Mechanical properties (EN 1.4307/AISI 304L)

|

Property |

Value |

|

Proof stress |

200 Min MPa |

|

Tensile strength |

500 – 700 MPa |

|

Elongation |

45 Min% |

|

Hardness |

215 Max HB |

Specifications (EN 1.4307/AISI 304L)

|

EN grade 1.4307 |

|

EN short name X2CrNi18-9 |

|

EN standard 10088-3 |

|

AISI 304L |

|

BS 304S11 |

|

JIS SUS304L |

|

Micro structure Austinite |

Rør og fittings – Den vitale ryggraden i hygieniske prosesser

Betydningen av rør og fittings i hygienisk produksjon kan ikke overvurderes. Ved å koble sammen alt prosessutstyr, sikrer de påliteligheten, effektiviteten, sikkerheten og bærekraften til prosessflyten.

Overlegen sikkerhet.

Designet for unik rengjørbarhet og full sporbarhet for å sikre integriteten til prosesser og produkter.

Uovertruffen pålitelighet

Eksepsjonell kvalitet, holdbarhet og lang levetid for å sikre høy driftstid og produktivitet.

Optimal effektivitet.

Konstruert for sømløs flyt og enkel rengjøring, noe som sikrer optimaliserte prosesser og økt utbytte.

Bærekraft i sentrum

Produsert og levert med bærekraft i tankene, noe som reduserer karbonavtrykket og oppfyller bærekraftsmålene.