Tri-Clover™: Revolutionizing hygienic process systems

In the world of hygienic process systems, the Tri-Clover™ brand stands out as a guarantee for quality and innovation. Renowned for its comprehensive range of tubes and fittings it has become synonymous with reliable and hygienic fluid handling for industries where cleanliness is of vital importance, like the food, beverage, pharmaceutical and biotechnology industries.

Tri-Clover tubes

Alfa Laval offers UltraPure tubes Tri-Clover BPE which are produced with the highest hygienic standards according to ASME BPE.

UltraPure tubes Tri-Clover BPE are available in:

- Sizes ½-4 inch (12.70-101.60 mm)

- EN 1.4404 / AISI 316L

- Surfaces SF1 and SF4

- Standard length - 20 feet (6100 mm)

Kontakt oss

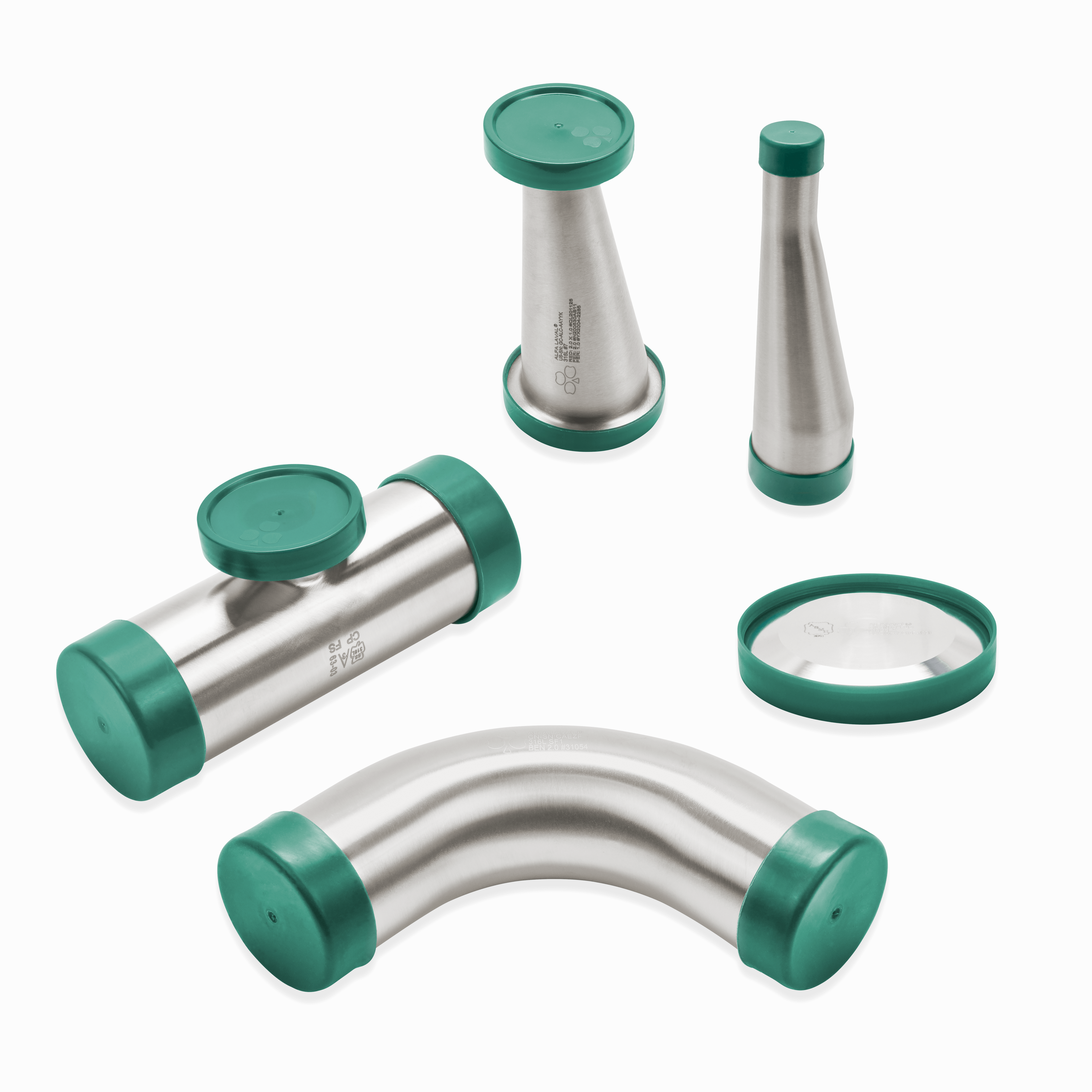

Tri-Clover fittings

Alfa Laval offers Tri-Clover fittings in two versions: Hygienic fittings Tri-Clover 3A and UltraPure fittings Tri-Clover BPE.

The Hygienic fittings Tri-Clover 3A are mainly used in the food, beverage, and home & personal care industries. They are produced according to the 3A standard.

Hygienic fittings Tri-Clover 3A are:

- Mainly available in the sizes 1-6 inch (25.4 – 152.4 mm)

- Produced in EN 1.4307 / AISI 304L and EN 1.4404 / AISI 316L

The UltraPure fittings Tri-Clover BPE are mainly used in the pharmaceutical and biotechnology industries, but can also be used for food, beverage, home & personal care industries – depending on the fluid to be transported through the process line. The UltraPure fittings Tri-Clover BPE are produced according to the ASME BPE standards.

UltraPure fittings Tri-Clover BPE are:

- Mainly available in the sizes 1-6 inch (25.4 – 152.4 mm)

- Available in EN 1.4404 / AISI 316L

- Available in surfaces SF1 and SF4

Historical context and evolution of Tri-Clover and Tri-Clamp

Tri-Clover was founded in the early 20th century, emerging at a time when the industrialization of food and beverage processing was gaining momentum. The initial focus of the company was to provide solutions that meet the stringent hygienic standards required in these industries. This was a period when traditional methods were being replaced by more advanced and hygienic processes, and there was a growing awareness about the importance of hygienic conditions in production.

One of the most significant innovations of Tri-Clover was the development of the Tri-Clamp fitting. This product revolutionized hygienic process lines with its simple yet effective design. The Tri-Clamp fitting, characterized by its four-part assembly comprising a clamp, a gasket, and two ferrules, offered an easy-to-use and reliable method to connect pipes and hoses in a hygienic manner. This innovation greatly reduced the risk of contamination, making it ideal for applications where cleanliness is critical.

Over the decades, Tri-Clover continued to grow and expand its product line. The company extended its reach into various sectors, including pharmaceuticals and biotechnology, where sterile processing environments are essential. Tri-Clover’s commitment to quality and adherence to industry standards helped solidify its reputation as a trusted brand in these sectors.

In 1991 Alfa Laval acquired Tri-Clover. This acquisition was part of Alfa Laval's strategy to expand its portfolio in the hygienic equipment sector and enhance its offering in the food, dairy, beverage, pharmaceutical and biotechnology industries. The Tri-Clover™ brand became a trademark of Alfa Laval and in many countries also a registered trademark, Tri-Clover®. In our day-to-day business we only use the trademark for our customers to recognize the strength of this product portfolio.

The incorporation of Tri-Clover into Alfa Laval's extensive range of components and services further strengthened the company's position as a key player within hygienic equipment. This acquisition allowed Alfa Laval to leverage Tri-Clover’s expertise and reputation in hygienic tubes and fittings thereby broadening its capabilities and market reach in these critical sectors.

As a side note Alfa Laval also obtained the brand name Tri-Clamp which is known specifically for a connection consisting of two ferrules, a seal and a clamp. While Tri-Clover is known for its state-of-the art quality in the entire hygienic processes, Tri-Clamp is known for this specifically type of connection.

No one else but Alfa Laval are allowed to use the trademarks Tri-Clover™ and/or Tri-Clamp.

Design and material excellence

At the core of Tri-Clover’s success is a commitment to design excellence and material quality. Predominantly crafted from high-grade stainless steel EN 1.4404 (AISI 316L), Tri-Clover equipment offers exceptional resistance to corrosion and wear. The choice of material is critical, particularly in applications involving acidic products, or where frequent cleaning is required.

Innovative features and benefits

Tri-Clover connections, characterized by their Tri-Clamp design, are a proof of the brand's innovative approach. This unique design simplifies assembly and disassembly, facilitating easy cleaning and maintenance, crucial in hygienic applications. The clamp mechanism ensures a secure connection, vital for maintaining product integrity and process efficiency.

Environmental and user safety

Tri-Clover's design principles also extend to environmental and user safety. The ease of cleaning and maintenance of the components not only reduces the risk of contamination but also minimizes the use of cleaning agents, contributing to environmental sustainability. Moreover, the ergonomic design of the tubes and fittings ensures user safety, reducing the risk of workplace injuries.

Moreover, the surface finish of Tri-Clover products is produced to meet strict hygienic standards. The polished, non-porous SF1 or SF4 surfaces minimize product adhesion, ensuring the highest levels of cleanliness. The internal surface finish, particularly, that have a Roughness average (Ra) < 0.8 µm for hygienic Tri-Clover 3A, (Ra) < 0.5 µm for Tri-Clover UltraPure and (Ra) < 0.4 µm for electropolish Tri-Clover UltraPure.

Adherence to standards and certifications

Adherence to industry standards and certifications is a cornerstone of the Tri-Clover philosophy. The products comply with various international standards, ensuring their suitability for global applications. These certifications not only reinforce the brand's commitment to quality but also provide users with the assurance of safety and reliability.

Applications across industries

The versatility of Tri-Clover products is evident in their widespread use across multiple industries. In the food and beverage sector, they are integral in handling dairy products, beverages, and processed foods. The pharmaceutical and biotechnology industries rely on them for the sterile processing of medications, while biotechnology applications benefit from their precision and cleanliness